Back to Growth: Smart Pricing Strategies to Boost Aftermarket Business

Transform your aftermarket strategy. Discover AI-driven pricing tactics and actionable insights from our expert-led webinar.

This onboarding guide will provide insights on implementing market-based pricing, including the potential benefits and steps to initiate a market-based pricing strategy.

The onboarding guide will provide insights on implementing market-based pricing, including the potential benefits and steps to initiate a market-based pricing strategy.

Our customer success team supports our customers and partners from the initial analysis of their status quo, through the actual implementation and realization of their opportunities. With our Onboarding Guide based on a process plan, we actively support and ensure the success of our customers.

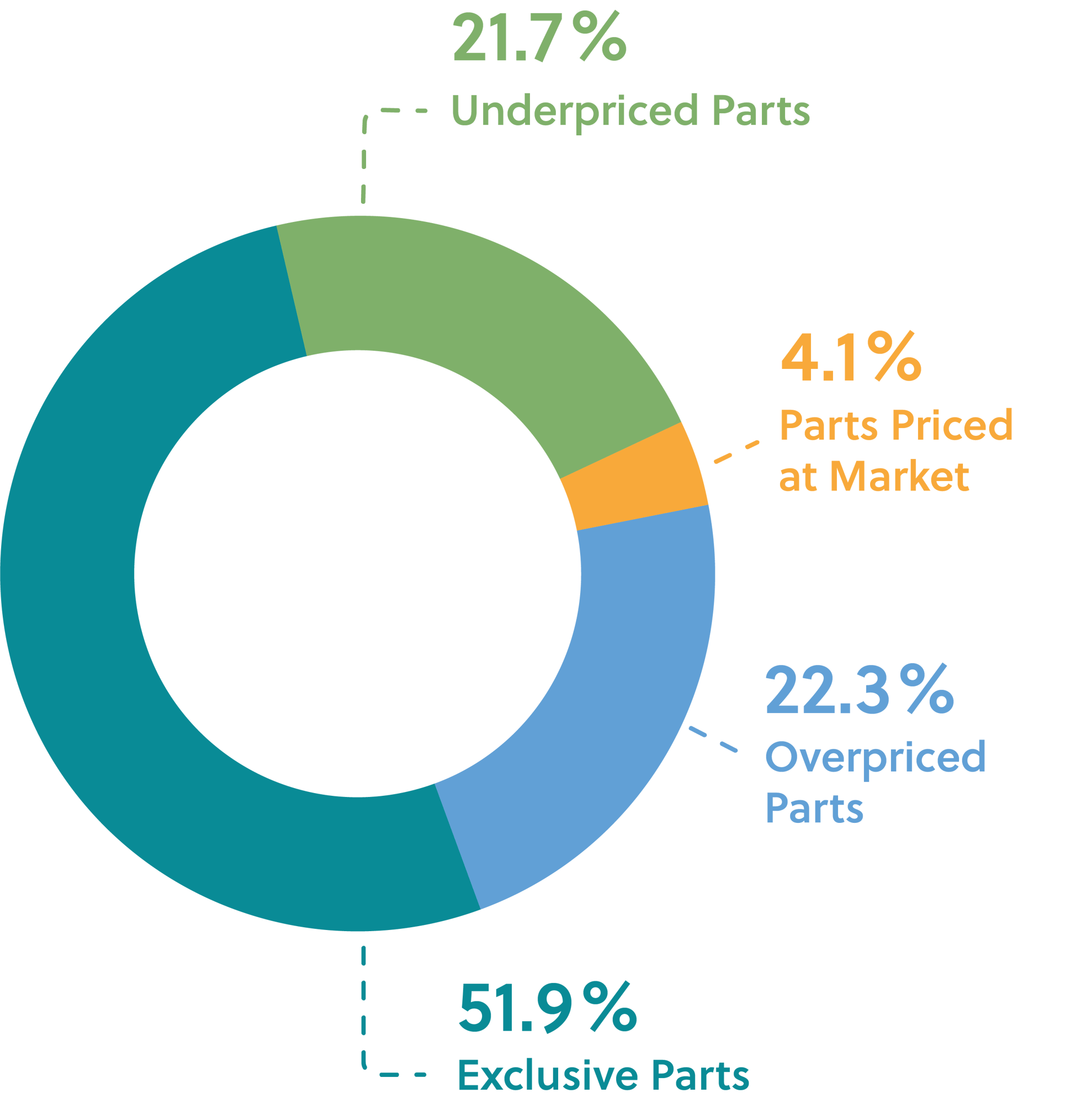

Currently, the market is becoming increasingly opaque for suppliers, while simultaneously becoming more clear for end customers. However, machine manufacturers have no way of creating market insights for 1,000 to 200,000 parts. Consequently, OEMs' prices and delivery times cannot be aligned with the market, which in turn leads to lost revenue potential. Existing data is also subject to a high degree of inaccuracy in terms of relevance and validity. MARKT-PILOT addresses this very issue and provides the basis for market-based pricing with automated market price research for spare parts.

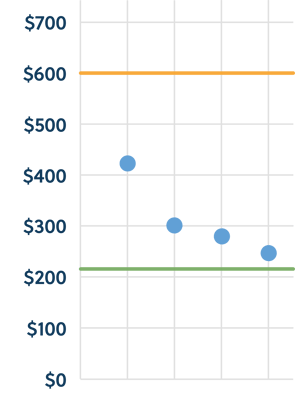

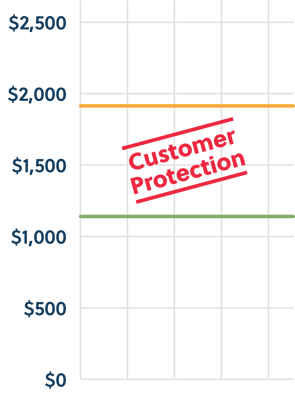

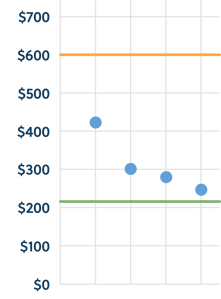

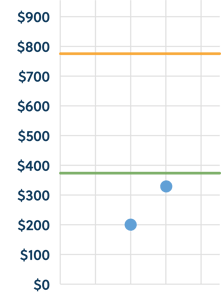

In pricing spare parts, one usually takes the purchase price of the item and calculates the sales price with a markup factor - in our example from + 150 to 400 percent. No information is available on competitors' prices, and as a result they are not taken into account in the pricing process. Nor are relevant factors such as win rate, market density or sales volume included.

In market-based parts pricing, competitors' prices are actively taken into account in the pricing process and a competitive markup or discount is applied. This method allows prices to be automatically aligned with the market and makes it easy to react quickly and dynamically to massive price changes by competitors, for example.

Market-based pricing uses artificial intelligence in machine manufacturing: Conventional pricing strategies are outdated and leave valuable revenue potential untapped in today's digital environment.

Machine manufacturing companies can tie their pricing strategy to current market data and use this information to increase or decrease prices for spare parts that were previously priced using the standard mark-up. In many cases, market-based spare parts pricing can boost the after-sales business and transform it from an appendage to an essential part of the business model of any machine manufacturing company. Market-based parts pricing connects machine manufacturers more closely with their customers: With competitive, fair pricing, customer confidence increases, and as customer confidence and purchasing increases, margins on spare parts increase.

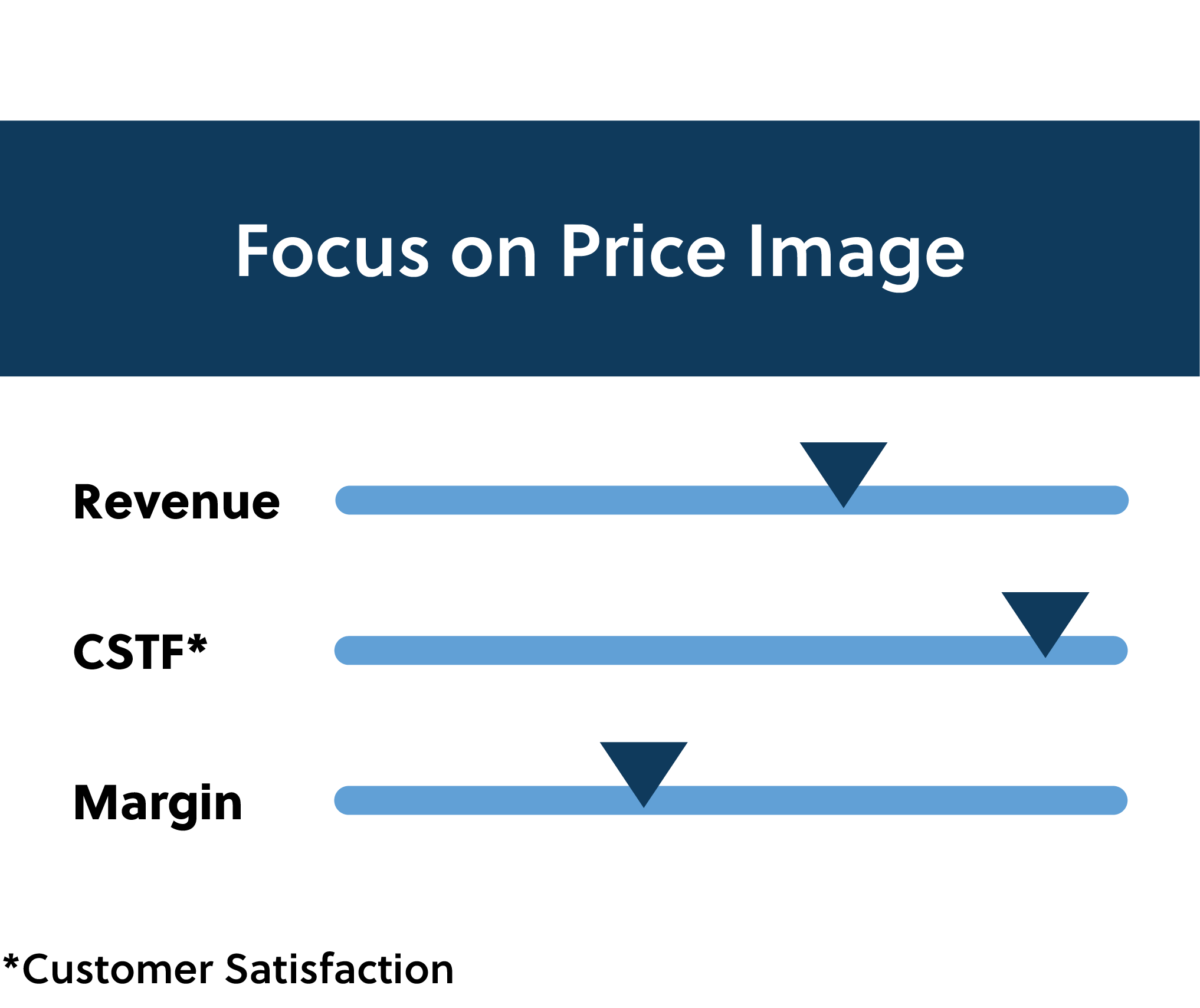

The focus is on optimizing and improving the price image: Here, only those parts that are too expensive are adjusted

The aim is to ensure that end customers do not perceive the company in question as expensive (anymore).

Optimizing the price image with intelligent price reductions maximizes customer satisfaction on the one hand, because price promises can be made, and market share potential on the other. Increasing cross-buying can also generate additional sales, for example with services, conversions, upgrades or new machines.

This strategy focuses on sustainable and long-term sales maximization.

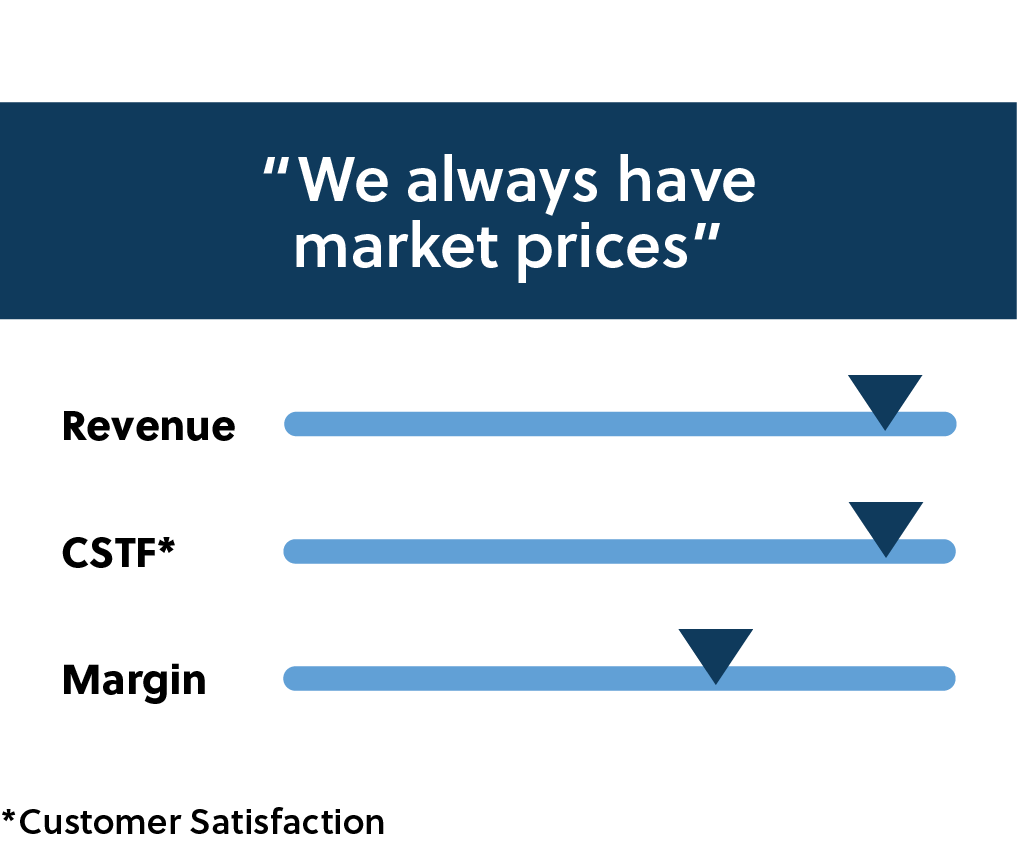

With this strategy, all sales prices are consistently adjusted to the market.

The goal is for end customers to purchase all parts directly from the machine manufacturer, as the latter always offers a fair price in line with the market.

This is often referred to as a trade-off between optimizing sales, margins and customer satisfaction. Increased customer satisfaction and loyalty also results in a great willingness to cross-buy for other services, rebuilds, upgrades and new machines.

This strategy focuses on equally on maximizing revenue and customer satisfaction.

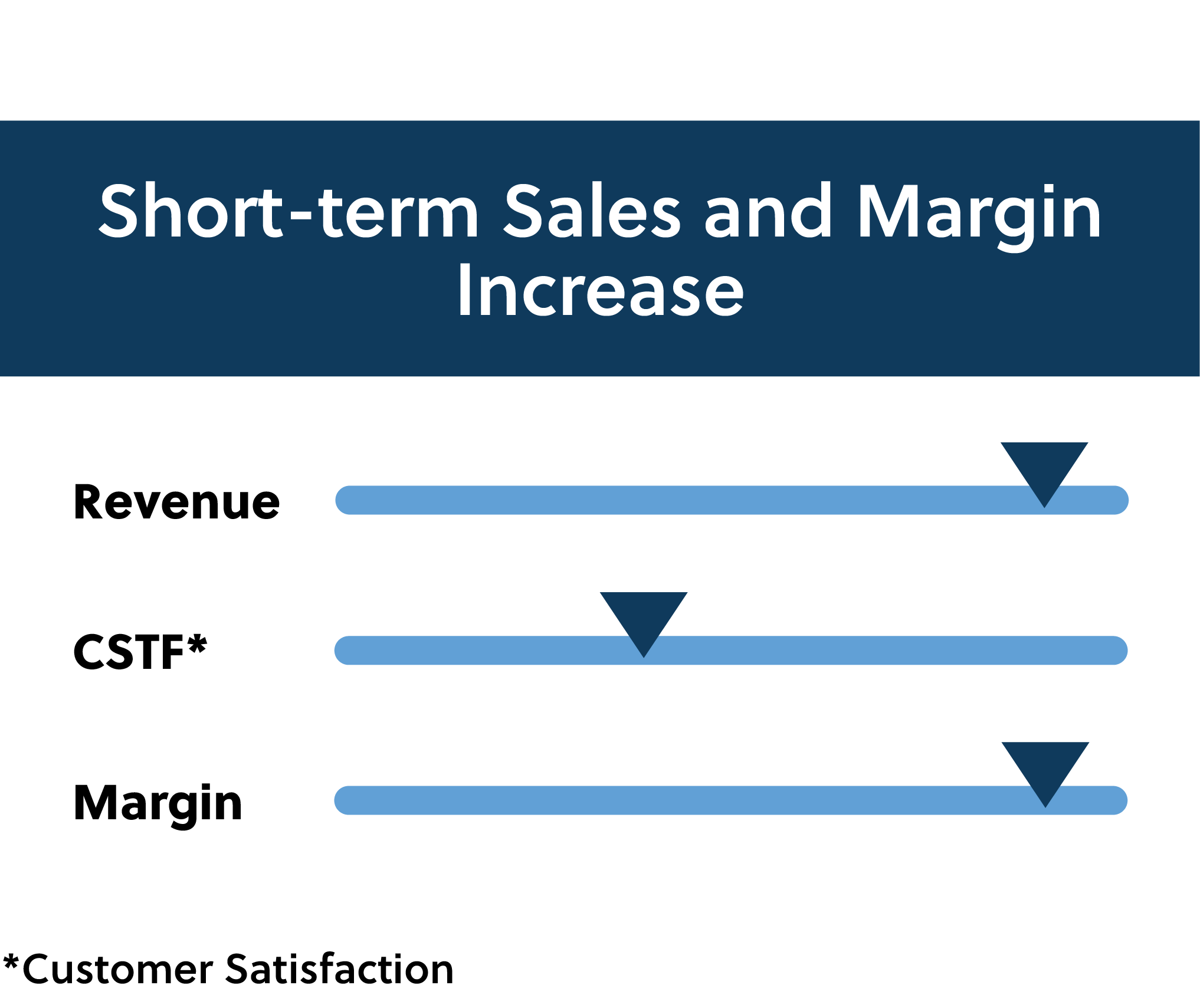

This strategy focuses on short-term sales and margin growth.

The aim is to maximize sales and margins by exploiting price and monopoly potential.

Stefan Deuschle, Head of Customer Success at MARKT-PILOT

Keep up with the pulse of the market and make informed pricing decisions based on current and reliable market data. In this guide, you'll learn how and why.

Intelligence about the existing, own position on the market is essential nowadays to remain lucrative and resilient. This is the basis of our solution and provides the respective data of your spare parts to the potentials: price increase, exclusivity position, market share increase and purchase optimization.

Price Increase

Raising sales prices to market price levels.

Exclusivity

Room for shift in pricing due to knowledge of monopoly position.

Increase Market Share

Increase win-rate, improve price image, strengthen cross-selling.

Optimize Purchase

Negotiate thoughtfully and find new suppliers.

Next, we will go through the existing potentials together and do a plausibility test - validating the results once again by defining value drivers and then forming intersections from them.

Using market share potential as an example, we visualize the individual steps for realization and show you a few classic value drivers as examples.

Attractive prices are especially crucial for prominent parts. For spare parts that, for example, were offered three times more often than they were sold, a price reduction is a good idea. Here, it is then a matter of monitoring the hit rate. In the next step, low-performing customers should be identified and actively targeted. Specific parts can also be actively promoted with the price adjustment, and at the same time cross-buying can be used for other products.

Marketing is critical at this point. Learn here how to successfully communicate price reductions to your customers.

To what extent does a market-based pricing strategy using MARKT-PILOT's comprehensive price and delivery time data contribute to increasing sales and improving customer satisfaction?

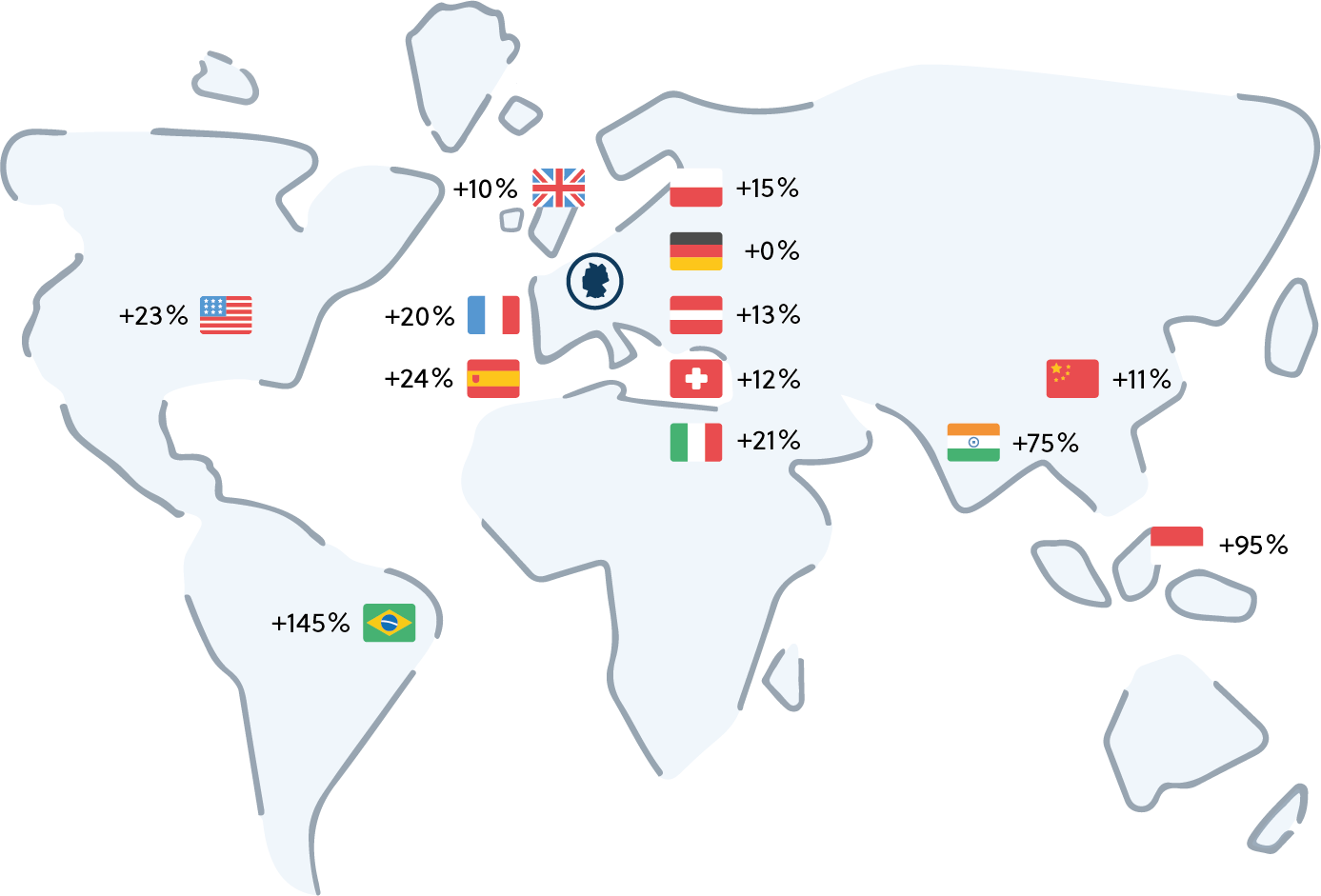

Different countries have different markets and those have different prices. Therefore, it is important to conduct separate research and appropriate pricing for different markets. Use the introduction of market-based pricing to introduce price adjustments with price harmonization within a market.

Another crucial point: involve dealers and subsidiaries in the pricing strategy. This also strengthens cohesion within a company's service business.

Deviation from the market price should only be allowed with justified and transparent cost presentation, for example due to customs, transport or currency hedging.

The pricing policy for spare parts is within the responsibility of the central service business of a mechanical engineering company. Nevertheless, it is relevant to involve the local units. However, this requires guiding principles for the delineation of tasks, competencies and responsibilities of the central and local services.

The responsibility for establishing the pricing policy of spare parts lies with the central service business of a mechanical engineering company. However, involving local units on site is crucial. To achieve this, it is necessary to establish clear guidelines that outline the tasks, competencies, and responsibilities of both the central and local services.

The central service unit is responsible for controlling global, service-relevant supply chain activities such as the spare parts warehouse, logistics, purchasing, shipping and returns. Decisions on the discontinuation of machine spare parts also take place centrally here.

In this area, the definition and control of KPI's, service support and the definition of the global pricing policy are the responsibility of the central site. Partner management and the development of new service products also lie here. The development of job descriptions takes place centrally, but in coordination with the local offices.

The local branches are responsible for local spare parts logistics and the management of the local spare parts warehouse.

Local service management (e.g. controlling, cash management and administration) and local pricing based on the global pricing policy take place in the local subsidiaries. For the local service portfolio, the subsidiaries identify local market potential, for example to meet specific local requirements. Partner management can also take place locally at this level.

When communicating price adjustments, it is important to communicate actively and frequently with the customer, preferably through known contacts - in the case of major customers, through senior executives. The realization of market share potentials can be supported in marketing terms with advertising measures - for example, via a special promotion for price-reduced wear parts.

Intelligence is also crucial here: Price information on individual parts should be made easily accessible to the customer, for example via a web store. Whether customers are satisfied can then be determined at best via permanent surveys.

Spare parts that are not selling well should be identified, and the customer can then be targeted and proactively addressed. This works in the same way for low-performing customers.

"Our customers should buy all spare parts from us" - that is the goal. With a price promise, one sets a confidence-building measure and supports the objective.

The strategy for increasing market share primarily involves reducing prices for prominent parts, such as wear parts, and actively advertising them.

In order to be able to react optimally to customer inquiries and to be prepared, price and purchase analysis make sense when required and support customer loyalty.

+5-15% p.a.

+10-30% p.a.

30% at 50%

+30% (at parts level)

Market-based pricing can provide various performance indicators, including delivery times, net promoter scores, sales from cross-selling, and cost savings in procurement. It's also possible to identify popular spare parts and those that require active promotion due to poor performance. Additionally, the urgency of spare parts and turnover rate can be evaluated based on delivery times.

Transform your aftermarket strategy. Discover AI-driven pricing tactics and actionable insights from our expert-led webinar.

Master price communication for spare parts! Learn strategies to navigate price adjustments & build trust. Retain customers now!

ISO 27001 Certified: MARKT-PILOT, your trusted partner for secure spare parts pricing. Rely on our certified data security to protect your business.