Unlock Revenue with Price Optimization Software

Optimal pricing is essential to stay competitive and price optimization software plays a key role in this process. In our guide, you get the key benefits and a step-by-step process for implementing a pricing solution. Read now!

Key Takeaways

💡 Price optimization software helps machine manufacturers set market-based prices using real-time data, increasing profitability and competitiveness.

💡 Pricing optimization replaces outdated cost-plus pricing with AI-driven, dynamic strategies that adapt to market fluctuations and customer expectations.

💡 Key benefits include increased margins, simplified pricing processes, improved customer satisfaction, and continuous performance monitoring.

💡 MARKT-PILOT offers tailored solutions for machine manufacturers, enabling confident, data-backed pricing decisions with proven customer success.

Content

01 What Is Price Optimization?

02 Why Price Optimization Matters for Machine Manufacturers

03 Key Benefits of Price Optimization Software

04 How Does Price Management Software Work? From Data to Decision

05 How to Choose the Right Price Management Software

06 Why Our Customers Choose MARKT-PILOT for Their Price Optimization Software Needs

What Is Price Optimization?

Price optimization means developing the best pricing strategy for products and equipment by analyzing market conditions, customer demand, and costs. This process relies on data-driven insights, including competitive analysis, dynamic pricing models, and historical sales trends, to strike the right balance between maximizing profitability and staying competitive in the market.

A price optimization software is a digital solution designed to help determine the most effective pricing strategies for products and parts. Such software analyzes comprehensive market data, such as competitor pricing, supply and demand trends, and customer behavior, allowing companies to set prices that increase profitability while staying competitive. It can automate the gathering of competitor prices and lead time information, providing clear insights into market position and revenue opportunities. Furthermore, it offers intelligent, validated pricing recommendations, helping business adjust prices with confidence.

Optimize pricing strategies with software allows to move beyond traditional cost-plus pricing models and embrace dynamic, market-based approaches that respond in real-time to market fluctuations, ultimately leading to increased sales and more satisfied customers.

Why Price Optimization Matters for Machine Manufacturers

Price optimization plays a critical role, helping companies adapt their pricing decisions to market shifts, manage cost pressures, and maintain profitability. By improving their pricing processes, businesses can future-proof themselves against industry challenges. Therefore, using price optimization software helps machine manufacturers to optimize their pricing and deal with:

Increased Competition in Domestic and International Markets

The machine manufacturing industry faces growing competition both locally and globally. Companies must differentiate through:

- Market-aligned pricing to remain competitive.

- Innovation in pricing models to attract and retain customers.

- Enhanced customer engagement through dynamic pricing strategies.

Additionally, geopolitical tensions and tariff and trade conflicts introduce significant complexities to the machine manufacturing industry. The U.S. administration’s recent imposition and subsequent retraction of 25% tariffs on imports from Mexico and Canada as well as the tariffs it has placed on imports from China have caused uncertainty within the industry. This could increase production costs, making U.S.-made machinery less competitive globally, and triggering retaliatory tariffs that reduce export demand. The tariffs also create market uncertainty, discourage investment, and contribute to stock market volatility. Additionally, domestic supply may not be sufficient to offset the higher costs, further straining manufacturers. These developments mean that machine manufacturers have to find ways to strategically adapt and also underscore the need to closely monitor geopolitical events and trade policies, as they can have direct implications on their pricing processes, operational stability and profitability. Pricing optimization is getting even more critical to remain competitive under these circumstances.

Evolving Customer Expectations and the Need for Digitalization

Customers now demand greater transparency, efficiency, and personalized solutions. To meet these expectations, machine manufacturers must adopt digital tools and data-driven strategies for their pricing optimization strategies. Digitizing different processes in the machine manufacturing industry can increase efficiency and unlock new revenue streams. With AI-powered price management software, machine manufacturers can effectively implement optimized market-based and dynamic pricing strategies to better meet customer needs.

Market Volatility

Fluctuating raw material costs, supply chain disruptions, and inflation make stable pricing challenging. Machine manufacturers require real-time market insights to adjust prices swiftly and protect profit margins. Advanced price optimization software offers enhanced analytics and AI integration, enabling quick responses to market changes and maintained profitability.

Rising Cost Pressures

Increasing production and operational costs lead to margin compression. Detailed pricing optimization identifies opportunities for higher margins without compromising sales volume. By implementing price optimization tools, maximum revenue potential can be ensured while maintaining competitive pricing, thereby enhancing profit margins.

Key Benefits of Price Optimization Software

Price optimization software offers substantial benefits to machine manufacturers who want to improve their pricing strategies. Here are some of the main advantages:

Improved Profit Margins

- Beyond Cost-Plus Pricing: Traditional cost-plus pricing methods often fail to capture the optimal value of products. Price management software enables machine manufacturers to move beyond these approaches by using real-time pricing insights to identify the best price points for each product and spare part.

- Enhanced Profitability: By determining optimal prices based on current market conditions, machine manufacturers can achieve higher profit margins without jeopardizing sales volume.

Simplified Pricing Processes

- Automation of Pricing Processes: The intricate nature of the machine manufacturing industry makes manual pricing both challenging and prone to errors due to the sheer number of parts in a company’s portfolio, for example. Price optimization software automates price calculations, ensuring consistency across global markets, diverse product lines, and various customer segments.

- Simplified Price Management: Price optimization software helps to streamline price list management, reducing manual workloads and minimizing errors. By analyzing historical sales data, market trends, and customer behavior, pricing managers have better insights into how price changes influence demand.

Long-Term Pricing Success

- Continuous Monitoring and Reporting: Price optimization tools provide ongoing tracking of price performance, allowing machine manufacturers to identify underperforming products, establish dynamic pricing and adjust strategies in real-time.

Data-Driven Insights

- Access to real-time market intelligence is crucial for informed decisions regarding pricing optimization, production, and sales strategies. Using this intelligence enables businesses to anticipate market shifts, adjust pricing accordingly, and optimize revenue in response to changing conditions.

Competitive Edge

- Real-Time Market Insights: Software for price managementoffers real-time data on market trends and pricing practices of the competition. This enables machine manufacturers to adjust their pricing strategies dynamically, ensuring they remain competitive in both domestic and international markets.

- Proactive Strategy Development: With access to up-to-date market intelligence, machine manufacturers can anticipate shifts in demand and respond swiftly, maintaining a competitive advantage.

Enhanced Customer Satisfaction

- Market-Based Pricing: By using price optimization software, machine manufacturers can set prices that reflect current market conditions and customer expectations. This alignment builds trust and establishes the company as a fair and reliable service provider.

- Transparency and Fairness: Implementing transparent and fair pricing strategies builds customer trust, leading to increased satisfaction and loyalty.

Optimize Your Pricing with Market Intelligence

Extensive Market Intelligence is key for succesful pricing strategies. In our whitepaper Market Intelligence in Machine Manufacturing, you will learn everything about market intelligence and the role it plays in the aftermarket of machine manufacturing.

How Does Price Management Software Work? From Data to Decision

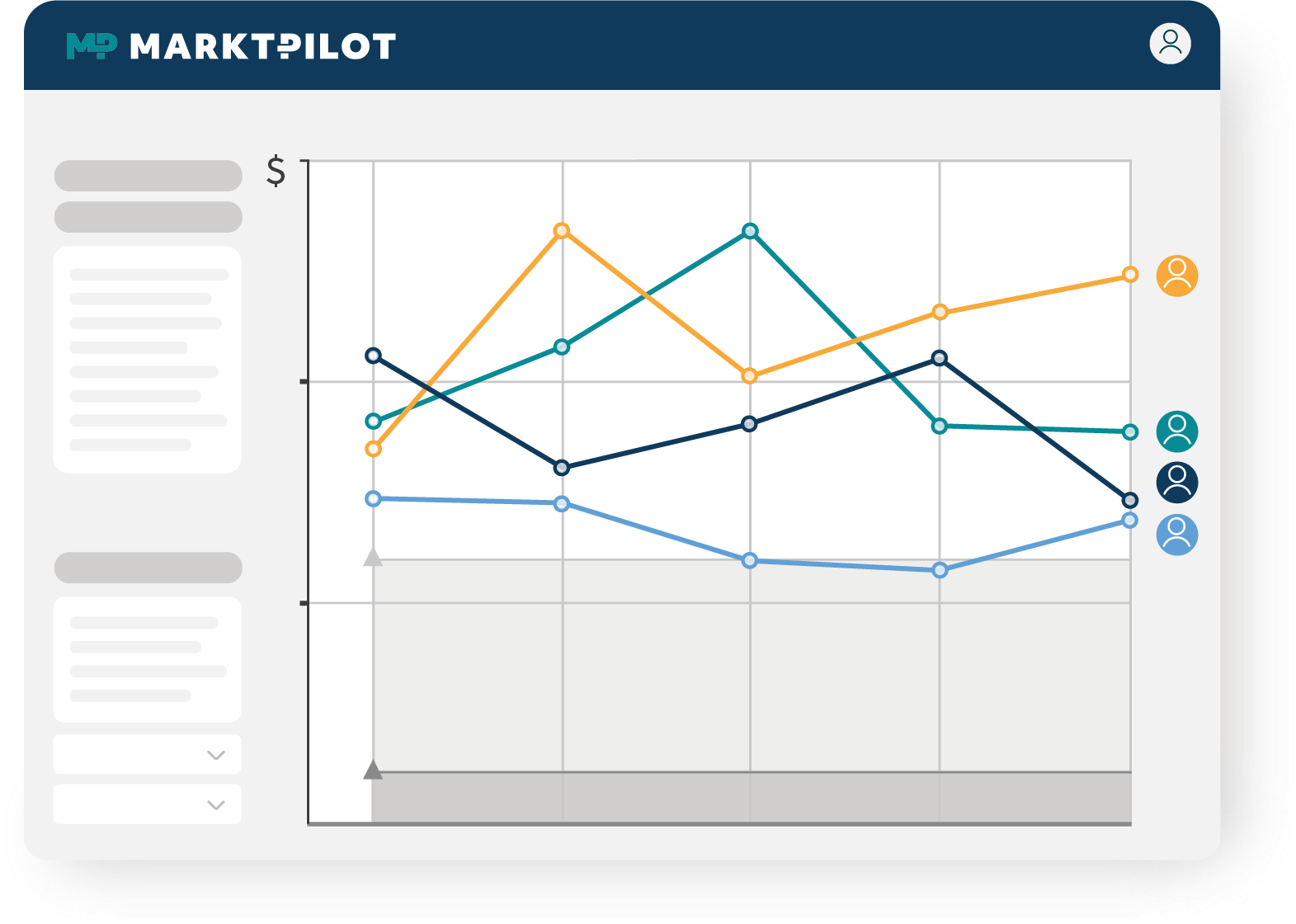

Price optimization software uses advanced data analytics and artificial intelligence to determine the optimal price point for products and spare parts. It collects extensive market data – including competitor prices, availability, and lead times – and integrates seamlessly with existing enterprise systems like ERP and CRM platforms, ensuring real-time data synchronization.

By using historical sales data and market trends, the software predicts future product demand and assesses how price changes affect this demand. Employing dynamic pricing models, it adjusts prices in real-time based on fluctuations in factors such as raw material costs, supply chain disruptions, and competitive actions.

Machine manufacturers can simulate various pricing optimization strategies and their potential outcomes, facilitating informed decision-making. Once optimal prices are determined, the software can update pricing across sales channels, supporting sales teams in their work. Continuous monitoring of pricing strategies enables underperforming products to be identified and real-time price adjustments to be made to maintain competitiveness.

Customizable dashboards display key performance indicators, providing insights into the effectiveness of pricing strategies, while real-time market intelligence allows machine manufacturers to anticipate market shifts, adjust pricing, and optimize revenue in response to changing conditions.

What Are the Common Pricing Challenges to Overcome?

- Supply Chain Volatility: Unpredictable supply chains lead to fluctuating prices, making it difficult to maintain stable and competitive pricing for spare parts.

- Complex and Large Portfolios: Spare parts inventories often contain thousands of items. Managing such extensive portfolios adds complexity to the pricing process for machine manufacturers, especially when considering market dynamics and varying characteristics, such as material composition, size and specifications, functionality, durability and lifespan, and market demand and availability.

- Traditional Pricing Methods: Reliance on outdated cost-plus pricing strategies can result in prices that are not aligned with current market conditions, leading to missed revenue opportunities.

- Manual Pricing Processes: Manual pricing is time-consuming and prone to errors, making it difficult for machine manufacturers to quickly respond to market changes and optimize pricing strategies accordingly.

- Competition from Alternative Suppliers: The rise of online marketplaces and third-party suppliers gives customers more options, increasing price transparency and putting pressure on manufacturers to adjust their pricing strategies more frequently.

Addressing the challenges above requires advanced pricing optimization strategies. With AI-powered price optimization tools, machine manufacturers can analyze market data, automate processes, and set market-based prices that enhance their profitability and competitiveness.

How to Choose the Right Price Management Software

Selecting the appropriate price management tool is crucial for machine manufacturers aiming to optimize pricing strategies. The following table outlines key considerations to guide your decision:

By evaluating these factors, machine manufacturers can select software that not only align with their current operational needs but also support future growth and market competitiveness.

Benefits of Market-Based Pricing for OEMs

Market-based pricing enables machine manufacturers to optimize their spare parts pricing. Our Ultimate Guide for Marked-Based Parts Pricing provides the key knowledge and tools to increase competitiveness in the parts business.

Why Our Customers Choose MARKT-PILOT For Their Price Optimization Software Needs

Customers choose MARKT-PILOT because of its comprehensive and innovative solutions that are specifically tailored to meet the needs of the machine manufacturing industry. With MARKT-PILOT, machine manufacturers can implement data-driven, market-based pricing strategies for their spare parts portfolio. By automating the collection of pricing data of competitors and lead times from over 10.000 data points, MARKT-PILOT provides transparent insights into market positioning and revenue potential.

By using MARKT-PILOT's technology, manufacturers can conduct market-based pricing analysis with precision, ensuring their pricing models remain competitive and can use intelligent, validated pricing recommendations to adjust prices confidently and improve their profitability with optimized prices.

MARKT-PILOT’s dedication to delivering cutting-edge technology and tailored solutions has led to significant revenue growth and improved customer satisfaction for machine manufacturers, making it a trusted partner for pricing optimization needs.

MARKT-PILOT aftermarket pricing solutions offer:

- Assistance in implementing the market price information

- Carrying out a risk analysis by considering critical value drivers

- Defining a parameter by which to measure the confidence level of pricing decisions.

- Minimizing manual effort to arrive at a successful pricing decision across a larger number of parts

- Revenue simulation making revenue and margin visible and predictable

PRICERADAR enables data-based and intelligent pricing decisions thanks to first-time transparency on competitors, prices and lead times. PRICEGUIDE takes the guesswork out of pricing. By harnessing its smart, data-driven insights, machine manufacturers can improve pricing quality while steadily increasing spare parts sales over time.

Market insight is the key to a successful competitive parts pricing strategy.

Simple Implementation

Ready to use in less than 30 minutes. No integration or training required.

Accurate Results

MARKT-PILOT takes over market price research for spare parts and delivers validated results through a 1:1 comparison.

+10,000 data points

Access to validated data points from various online and offline sources for unrivaled data accuracy.

Customer Success Story: LTW Intralogistics GmbH

THE CHALLENGE

Static price lists and reactive price adjustments no longer meet current market demands, which is why the traditional cost-plus logic needs to be rethought. Especially in dynamic and volatile times, one of the greatest challenges in the service sector is meeting the continuously changing customer requirements while ensuring stable revenue streams.

Thomas Narbeshuber, Business Unit Manager Service at LTW Intralogistics GmbH, aptly summarizes the current situation in service: "The challenge in after sales is to meet the constantly changing requirements of customers as a logistics supplier, especially in increasingly dynamic and volatile times." But how can these processes be made sustainabily efficient and profitable?

MARKET-BASED PRICING STRATEGIES TO OPTIMIZE PRICING AND FOSTER TRUST

SOLUTION

The solution? To maintain competitiveness, an intelligent pricing strategy is imperative. This entails creating a simple pricing model seamlessly integrated into existing processes and easily maintained.

With the implementation of MARKT-PILOT, LTW Intralogistics has adopted a lean and scalable solution, positioning the company as a fair and reliable partner for its customers in terms of both availability and prices.The software's swift deployment without the need for extensive implementation enables a quick start.

Conclusion: Price Optimization Software in Machine Manufacturing

Implementing price optimization software is essential for machine manufacturers to improve the overall pricing performance. By embracing data-driven pricing strategies, automating complex pricing processes, and using real-time market intelligence, machine manufacturers can increase profitability, streamline operations, and better meet customer expectations.

Partnering with solutions like those offered by MARKT-PILOT can further help machine manufacturers with their pricing optimization efforts, leading to sustained success and market leadership.

Download Guide: Pricing Software for Machine Manufacturing

FAQs

What Is Price Optimization?

Price optimization means creating the most effective pricing strategy for products by analyzing a range of factors, including market conditions, customer demand, competitor pricing, and production or operational costs. The goal is to determine a price point that maximizes both sales and profitability while remaining competitive in the market and appealing to customers.

What Is Price Optimization Software?

It’s a type of software that can help machine manufacturers to set optimal prices by analyzing market data like competitor prices, demand, and customer behavior, enabling dynamic, real-time price adjustments.

Why Is Price Optimization Software Important?

It helps machine manufacturers stay competitive, adapt to market changes, manage costs, and meet customer expectations, ultimately boosting profitability and satisfaction.

How Does Price Optimization Software Work?

It collects and analyzes market data, and based on the data makes price recommendations, automates pricing processes, and provides real-time insights to ensure competitive pricing.

What Are the Main Benefits of Price Optimization Software?

It maximizes profit margins, simplifies pricing for large inventories, ensures long-term success, and enhances customer satisfaction with market-based pricing.

How Can Manufacturers Choose the Right Price Optimization Software?

Machine manufacturers should assess business needs, evaluate features like automation and real-time data, ensure system integration, and prioritize scalability and vendor support.